m+p Analyzer vibration Analyzer

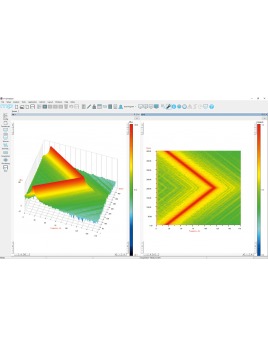

- multi-channel real-time FFT Analyzer,

- Recorder function (time data recording on hard disk),

- Modal analysis (SDOF, MDOF), impulse hammer test,

- Operating Deflection Shapes (ODS),

- Torsional vibration analysis,

- Measurement and analysis of sound,

- Pre-accession drive measurement (pass-by noise measurement)